Step 1

Drain Tank and allow it to dry inside

Step 2

Pass an electric soldering iron or similar hot

instrument lightly over the hole working molten

plastic into the hole.

Step 3

Allow patch to cool and test the tank with

water. If the tank still leaks, allow it to dry

again and REPEAT STEP 2.

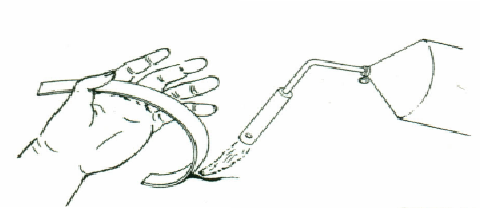

Step 4 For larger holes use a strip of polyethylene

repair plastic as shown. Carefully heat the tank

at the point to be repaired with a propane torch

on low heat.Do not melt the plastic as melted

plastic loses its physical properties. The two

materials should be slightly tacky.

Extreme caution must be used to avoid

overheating

Stress Cracks

Stress cracks are commonly cause by an

improper tank installation and/or overfilling

the tank. This is typical of tanks that are

over 20” that have not been fully supported.

To repair a stress crack, drill a small hole at

each end of the crack and continue heating

plastic together along the crack. Overlap

Each end 1” if possible.

Major repairs can be done at the Inca

Factory .